We are committed to food packaging PVC cling film, PE cling film,stretch wrap, aluminum foil and other disposal food packing film/foil.

Language

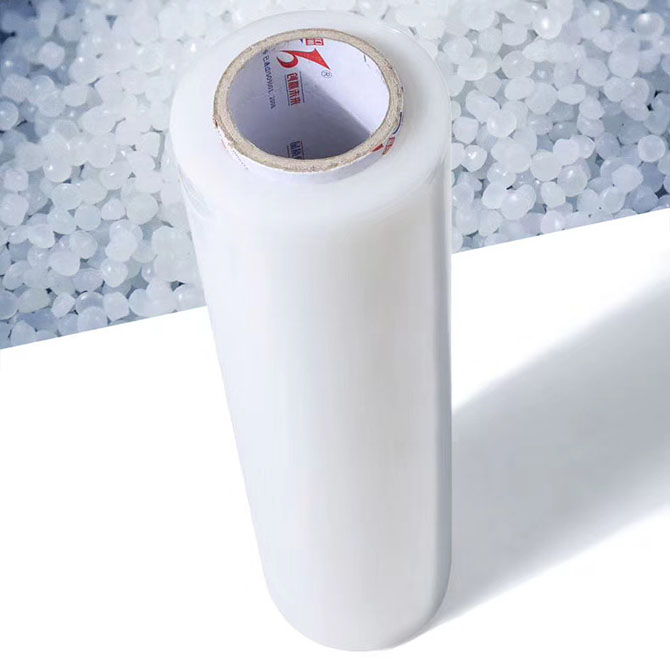

>When it comes to packaging, the first thing that comes to mind is "conspicuous" packaging tools such as cartons and tapes, but in fact, there is a kind of packaging material that is the "unsung hero" behind the scenes - it is Machine Stretch Film. This stretch film automatically wrapped by the machine not only makes packaging more efficient and less costly, but also protects the safety of goods. Next, let's talk about its several characteristics and application stories in actual work.

1. Improve efficiency and save a lot of labor

If you have ever seen manual packaging, you may understand the boredom: workers need to hold stretch film and keep turning around the goods, which is both laborious and time-consuming. Once the machine stretch film comes on stage, the packaging speed increases instantly. For example, there is an electrical appliance manufacturer in the United States that used to rely on manual packaging and could only handle 20 pallets per hour at most. After switching to machine stretch film, the efficiency doubled directly, and 40-45 pallets were handled per hour. The packaging speed is faster and the labor cost is greatly reduced. This kind of automated packaging not only makes workers relaxed, but also saves the company a lot of money.

According to data from AMR Research, automated packaging can reduce the labor costs of enterprises by an average of 30%. This "saving tool" is definitely not just talk. Especially in the peak season with a large number of orders, with machine stretch film, workers do not have to work overtime day and night, the packaging pressure is reduced, and the work experience is naturally better.

2. Tight packaging makes the goods more stable

During transportation, it is actually quite common for goods to slide and tip over, especially when the force is uneven during manual packaging, the film is wrapped loosely, and it is easy to shift when it encounters bumps. However, it is different when it is replaced with machine stretch film. It can automatically wrap according to the preset tension to ensure that the tightness of each layer of film is consistent. There is such an example of a large e-commerce warehousing company in the United States. After switching to machine stretch film, the damage rate of goods transportation directly dropped by 15%. The reason is simple: the packaging is tight, and the goods are not so easy to shake on the car.

Warehouse Research's survey also shows that machine stretch film can increase the stability of goods by 20% and reduce accidental damage. For some heavy or fragile goods, this stability is simply a "lifesaver". After all, no one wants customers to see a mess when they open the package.

3. Save materials, save money and be more environmentally friendly

Traditional manual packaging will result in some material waste. For example, workers may wrap the film a few more times because they are worried that it is not tight enough, which will increase the cost and waste. However, machine stretch film is different. It automatically controls the amount used, just enough to stabilize the goods and avoid unnecessary winding. For example, after a food processing company switched to machine stretch film, the packaging material cost per product dropped by 10%. It doesn't seem much, but in terms of volume, this cost saving is considerable.

Smithers Pira's research further proves this point: machine stretch film can reduce packaging material waste by 20-30%. In other words, while reducing costs and increasing efficiency, it can also contribute to environmental protection. For many companies, saving money and environmental protection are win-win, so why not?

4. Strong adaptability, all kinds of goods can be handled

There are all kinds of goods on the market, whether they are small parts or large household items, there are always irregular shapes and strange specifications. The flexibility of machine stretch film in this regard is very considerate. It can automatically adjust the tension and number of wrapping layers according to the shape and weight of the goods, suitable for a variety of packaging needs. After a furniture company introduced machine stretch film equipment, it no longer had to redesign the packaging process for each piece of furniture. The automated equipment can easily adapt to products of different sizes and shapes, greatly improving work efficiency.

Flexport data also shows that machine stretch film is suitable for more than 90% of industrial packaging scenarios, especially large and heavy goods. In other words, this device is like a universal sticker, which can firmly stick to any goods, and there is no need to worry about packaging problems slowing down the progress of work.

5. Safer operation, workers no longer have to be exhausted

Manual wrapping sounds simple, but if you really do it for a day, the pain will only be understood by those who have experienced it. Bowing down for a long time to wrap the film and squatting and standing repeatedly to operate are actually a great burden on workers. The introduction of machine stretch film equipment is like giving workers an extra layer of protection. They no longer need to wrap the film manually. Just press a button and the machine will automatically complete it.

After a logistics company in the United States adopted machine stretch film, the incidence of work-related injuries among workers dropped significantly. The back pain caused by repeated wrapping has been reduced by 30%. According to the data of the Occupational Safety and Health Administration (OSHA), automatic packaging equipment has a significant effect in reducing work-related injuries, which not only reduces the burden on workers but also makes factories safer.

Summary

The seemingly simple machine stretch film has great application potential. It can not only improve packaging efficiency and save labor costs, but also make packaging more stable and prevent transportation damage. Moreover, automated equipment can accurately control the amount of materials used, saving costs and being more environmentally friendly. The flexibility and high adaptability of this equipment also allow it to handle almost all industrial packaging needs, whether it is parts or furniture, it can find a suitable packaging method.

In short, machine stretch film is like a silent "invisible hero" for enterprises. In the packaging process, it is a master of cost saving, a promoter of efficiency improvement, and a guardian of worker safety. The seemingly simple automatic wrapping equipment actually plays an indispensable role in all walks of life.